Zeus Specifications

- Robustly designed and constructed that will handle your most demanding applications

- Handle solids, heavy sludge, slurries as well as the toughest liquids. The Zeus Truck will pick up anything that can fit in an 8” hose!

- Available with up to 6600 CFM Positive Displacement blower

- Ultimate protection of blower using dual Cyclones to filter the air prior to the final filter.

- Washable inline blower filter to protect blower from fine particles

- 1000 USG of water in a front mounted internally coated water tank with optional vacuum loading capabilities

- 2600 USG Debris tank with internal baffle, full opening rear door and 8”x 26 ft reach x 6 way hydraulic boom that operates 320 degrees with standard wired pendant and optional Wireless system to remotely control the system.

- Various water pumps and hose reel configuration based on our needs.

- Water system is designed for your application in your area. Standard warm weather features with optional cold weather system to protect system in sub-zero environments.

- Configurable to suit your application. A variety of available options. See specifications on back

- The one truck that handles all of your heavy duty hydroexacavating needs!

The ZEUS SERIES is combination of decades of vacuum truck design and manufacturing experience with the superior quality that you have grown to know and expect from RUSH OVERLAND MANUFACTURING.

Standard Specification

Tank

- Designed for Full Vacuum, 15 psi for Internal pressure and 15 psi External pressure

- 2600 USG tank made of Carbon Steel

- Full opening Rear Door with dual side mounted hydraulic cylinders and Semi-automatic Door Saftey brace

- Hydraulic dump cylinder for dumping tank with Semi-Automatic tank safety stand.

- 6 Manual operated Polished Rear Door bolt and wing nuts

- 20” Manway on top of tank

- Primary shut-off mounted in 20” Manway. Easy access for removal and servicing through lid of manway.

- Rear door mounted Rotary Float Gauge

- 6” Manual suction valve mounted on rear head with 6” Standpipe, deflector plate with aluminum camlock and cap.

- 6” Manual discharge valve mounted on rear head

- Half baffle

- Hydraulic vibrator mounted on bottom of tank

Water Tank

- 1000 USG front mounted tank made of Carbon Steel internally coated with Tnemec 141 Epoxy

- 20” Manway located in to of tank

- 3” fill line with shut-off valve and camlock connection

Water pump feed line with shut-off valve with non-disconnect piping - 3” air operated drain valve

- Three 5” Sight glass

- 15 psi pressure relief valve.

Water System

- 18 GPM @ 2900 psi hydraulic driven water pump

- Unloader valve, safety relief valve, hand gun with quick disconnects

- Spring rewind hose reel and 100 ft of ½” hose

Bloom

- 6-way hydraulically operated 8” Boom extendable to 26 ft c/w with heavy duty boom hose and band lock fittings and 320 degree rotation.

- Wired pendant with 25 ft extension and optional wireless controls

- Three 8” x 60” diameter boom extension tubes mounted on the side of truck.

Positive Displacement Blower

- Roots DVJ 827 PDB capable of 5775 CFM and 27” full vacuum driven by heavy duty OMSI driveline mounted transfer case. Optional Robuschi/Gardner Denver RBD-145 or Hibon 8702 blowers available.

Vacuum System

- Modular subframe design

- Dual 20” Cyclone for filtration of airflow to minimize carry over with 20” drop box and 3” drain valves.

- 30” diameter final filter assembly with 100 micron washable inline filter to protect blower.

- 12” Check valve to protect blower from turning backwards.

- Dual 8” Disconnect piping to allow tank to dump.

- 6” manual vent valve and 6” Air-operated vent valve

- Blower over-temperature protection system

- Pressure relief valve

Trim

- Full length enclosed Hose trays with drain ports

- LED truck lighting with LED side markers – Fully FMVSS certified

- 2 LED rear mounted work lights, 2 side mounted work lights, and one work light mounted near control panel

- DOT rated bumper

- Easy Fold up ladder on driver side for access to manway and top of tank

- Weather sealed Tool Box

- Enclosed Control panel for protection of gauges

Chassis

- Mounted on Rush Supplied chassis or your chassis

Optional Equipment

- NVE re-buildable rear valves

- Stainless steel valves

- Custom Tool boxes

- Full length Catwalk Assembly

- Aluminum Side tray/Fenders

- Additional LED lighting

- Hydraulic operated door clamps

- Wireless boom controls

- Cold weather system – heated cabinets and valves, air purge systems and winterizing system

- 400,000 or 700,000 BTU/hr heater for cold weather operations.

- Various hose reel options

- Vacuum loaded water tank using hydraulically driven vacuum pump.

Notos Specifications

Featuring:

• Robust design and construction that will handle your most demanding applications

• Handles heavy sludge, slurries and the toughest liquids

• Minimizes material carry over from tank to filtration system

• Ultimate protection of the blower utilizing dual cyclones to filter the air prior to the final filter

• Washable inline blower filter to protect blower from fine particles

• Blower Over-temp Protection System (BOPS) prevents the blower from overheating when filter is

clogged

• Pressure offload your tank using the secondary vane vacuum pump

• Vacuum load your tank using the secondary vane pump for liquid loads and for operating in refineries

• Designed to carry hazardous material on the federal interstate highway system

• Maximum use of your truck axle weight limits on any road, federal highway or worksite

• Empty your tank without dumping all over your bumper using our PATENTED SLIDING TANK DESIGN

• Monitor your axle weights using the on-board air scales, reducing over weight tickets

ONE TRUCK FOR ALL YOUR HEAVY DUTY NEEDS!

Tank:

- DOT 407/412, ASME designed & certified for full vacuum, 25 psi for int. pressure and

15 psi ext. pressure - 3600 USG (+3% outage) tank made of carbon steel

- Full opening rear door with dual side mounted hydraulic cylinders with semi-automatic

safety brace - Hydraulic dump cylinder for dumping tank with semi-automatic safety stand

- 6 Manually operated polished rear door bolt and wing nuts

- 20” Manway mounted top of tank

- 8” Primary shut-off mounted top of tank with 8” and 3” air operated isolation valve

- Rear door mounted rotary float gauge

- 6” air operated suction valve mounted on rear head with 6” standpipe, deflector plate

and air switch - 6” air operated discharge valve mounted on rear head with air switch

- Half baffle

Positive Displacement Blower:

Roots DVJ 721 PDB capable of 3600 CFM and 27” full vacuum driven by heavy duty OMSI driveline-mounted transfer case. Blower Over-temperature Protection System (BOPS) designed to automatically protect blower from overheating.

Rotary Vane Pump:

PTO hydraulically driven moro, NVE, masport or optional rotary vane pump of your

choice controlled from valve body. 350-630 CFM (up to 28” Hg and 15 psi off-loading

pressure)

Vacuum System:

- Modular subframe design

- Dual 20” cyclone for filtration of airflow to minimize carry over with 20” drop box and

3” drain valves - 30” final filter housing with 100 micron washable inline filter to protect blower with

10” Check valve - 8” Disconnect and 3” non-disconnect piping to allow tank to dump

- 3” Secondary shut-off and oil catch muffler with 3” hose connection both with drain valves

- Pressure relief valve, vacuum relief valve and vacuum pump flush portaulically driven vacuum pump, powered by Muncie PTO, and Parker hydraulic valve body pumps and motors.

Trim:

- Full length enclosed hose trays with drain ports

- Fully FMVSS certified LED truck lighting with LED side markers and 2 LED rear-mounted

work lights - DOT rated bumper

- Easy fold-up ladder on driver side for access to manway and top of tank

- Weather sealed tool box

- SS control panel for tank vacuum/pressure gauge, hydraulic pressure gauge, emergency

shut-off switch, isolation valve switches, digital temperature gauge, digital tachometer

and throttle control - Hydraulic vibrator mounted to the bottom of tank

Chassis:

Mounted on Rush Supplied chassis or your chassis

Optional Equipment:

- Patented load boosting system designed to maximize your carrying capacity in any

state and prevent from dumping on your bumper - On board air scales for monitoring axle weights

- NVE re-buildable rear valves in steel or stainless steel

- Lined interior for tank for handling caustic material

- Custom tool boxes

- Transfer pump

- Full tank length catwalk assembly

- Aluminum side tray/fenders

- Additional LED lighting

- High-pressure wash down system

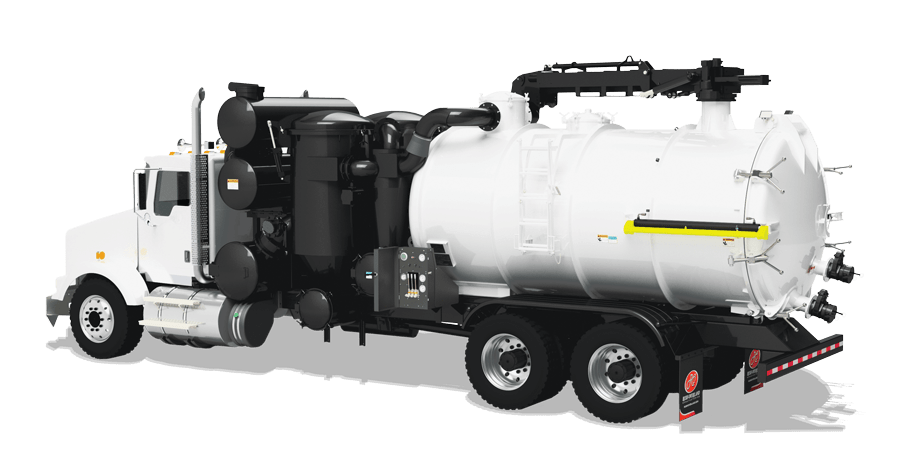

Talos Specifications

Tank:

- DOT 407/412, ASME

- Designed and Certified for Full Vacuum, 25 psi for Internal pressure and 15 psi external pressure

- 2000-3600 USG tanks available in Carbon Steel

- Full opening Rear Door with dual side mounted hydraulic cylinders

- Front head mounted Dump cylinder for dumping tank6 Manual operated Polished Rear Door bolt and Wing Nuts20” Manway

- 4” Primary shut-off mounted in 12” hatch with 4” Air Operated isolation valve Driver Side mounted Rotary Float gauge

- 4” Betts air operated Suction valve mounted on rear head with 4” Standpipe and deflector plate with air switch

- 6” Betts air operated Discharge valve mounted on rear head with air switch

- Bolt-on half baffle

Rotary Vane Pump:

Fruitland RCF870, NVE 866 or optional rotary vane pump of your choice

Vacuum Pump Drive:

Hydraulically driven vacuum pump, powered by Muncie PTO, and Parker hydraulic valve body pumps and motors.

CFM rating:

350-630 CFM (28” Hg, 15 psi off-loading pressure)

Vacuum system:

- Modular subframe design

- Secondary Shut-off and oil catch muffler with 4” hose connection both with drain valves.

- Pressure relief valve, vacuum relief valve

- 4” non-disconnect hose to allow tank to dump with hose connected.

Trim:

- Aluminum full length enclosed Hose trays with drain ports

- LED truck lighting with LED side markers – Fully FMVSS certified

- 2 LED rear mounted work lights

- DOT rated bumper

- Easy Fold up ladder on driver side for access to manway

- Weather sealed Tool Box

- SS control panel for Tank Vacuum/Pressure gauge, Hydraulic pressure gauge, emergency shut-off switch, rear valves switches and isolation valve switch

Chassis:

Mounted on Rush Supplied chassis or your chassis

Optional Equipment:

- Patented Load Boosting System designed to maximize your carrying capacity in any State

- High pressure wash down system

- Non- dumping tank

- Non-opening rear door

- NVE rear valves

- Polished Aluminum Diamond Plate Tool boxes

- Transfer Pump

- Full tank length Catwalk Assembly

- Additional lighting

Typhon Specifications

- Robustly designed and constructed that will handle your most demanding applications

- Handle solids, heavy sludge, slurries, liquids as well as light dry material. There isn’t anything that the TYPHON won’t pick up!

- Available with up to 6600 CFM Positive Displacement blower

- Ultimate protection of blower using dual Cyclones and dual baghouses to filter the air prior to the final filter.

- Dual baghouse with optional baghouse by pass system when loading wet material to extend the life of your bags.

- Washable inline blower filter to protect blower from fine particles

- 3600 USG Debris tank with internal baffle, full opening rear door and 8”x 19 ft reach x 6 way hydraulic boom that operates 320 degrees with standard wired pendant and optional Wireless controller to remotely control the system.

- Manual door bolts and wing nuts or optional hydraulic door locking system

- Optional secondary vacuum pump for pressure unloading or to handle smaller vacuum loading operations.

- Configurable to suit your application. A variety of available options. See specifications on back

- THE ONE TRUCK THAT HANDLES ALL OF YOUR HEAVY DUTY INDUSTRIAL CLEANUP AND RECOVERY NEEDS!

The TYPHON SERIES is a combination of decades of vacuum truck design and manufacturing experience with the superior quality that you have grown to know and expect from RUSH OVERLAND MANUFACTURING.

Specification

Tank

- Designed for Full Vacuum, 15 psi for Internal pressure and 15 psi External pressure

- 3600 USG tank made of Carbon Steel

- Full opening Rear Door with dual side mounted hydraulic cylinders and Semi-automatic Door

- Saftey brace

- Hydraulic dump cylinder for dumping tank with Semi-Automatic tank safety stand.

- 6 Manual operated Polished Rear Door bolt and wing nuts

- 20” Manway on top of tank

- Primary shut-off mounted in 20” Manway. Easy access for removal and servicing through lid of manway.

- Rear door mounted Rotary Float Gauge

- 6” Manual suction valve mounted on rear head with 6” Standpipe, deflector plate with aluminum camlock and cap.

- 6” Manual discharge valve mounted on rear head

- Half baffle

- Hydraulic vibrator mounted on bottom of tank

Boom

- 6-way hydraulically operated 8” Boom extendable to 19 ft c/w with heavy duty boom hose and band lock fittings and 320 degree rotation.

- Wired pendant with 25 ft extension and optional wireless controls

- Three 8” x 60” diameter boom extension tube mounted on the side of truck.

PD Blower

- Roots DVJ 827 PDB capable of 5775 CFM and 27” full vacuum driven by heavy duty OMSI driveline mounted transfer case. Optional Robuschi/Gardner Denver RBD-145 or Hibon 8702 blowers available.

Vacuum System

- Modular subframe design

- Dual 20” Cyclones for filtration of airflow to minimize carry over with 20” drop box and 3” drain valves.

- Dual 42” Baghouses with 59 individual bags and cages to further filter the air when loading light dry material. Baghouses are supplied with air blow down bag cleaning system, 20” drop box with 3” drain valves and hydraulically opening lids.

- 30” diameter final filter assembly with 100 micron washable inline filter to protect blower.

- 12” Check valve to protect blower from turning backwards.

- Dual 8” Disconnect piping to allow tank to dump.

- 6” manual vent valve and 6” Air-operated vent valve

- Blower over-temperature protection system

- Pressure relief valve

Trim

- LED truck lighting with LED side markers – Fully FMVSS certified

- 2 LED rear mounted work lights, 2 side mounted work lights, and one work light mounted near control panel

- DOT rated bumper

- Easy Fold up ladder on driver side for access to manway and top of tank

- Ladder and platform for easy access to baghouse bags

- Weather sealed Tool Box

- Enclosed Control panel for protection of gauges

Chassis

- Mounted on Rush Supplied chassis or your chassis

Optional Equipment

- NVE re-buildable rear valves

- Stainless steel valves

- Custom Tool boxes

- Full tank length Catwalk Assembly

- Aluminum or steel full length Side tray/Fenders

- Additional LED lighting

- Hydraulic operated door clamps

- 6-way hydraulically operated 8” Boom extendable to 23 ft c/w with heavy duty boom hose and band lock fittings and 320 degree rotation.

- Wireless boom controls

- Secondary Vacuum Pump for pressure unloading and smaller vacuum loading applications.

- Vacuum pump options (Fruitland, Moro, NVE, or Masport)

- Rear door mounted upper loading nozzle

- Rear mounted hose Hooks